Maintain the Equipment in your Organization using Odoo ERP Maintenance Module

When equipment is bought in an Organization, it is the prime responsibility of the maintenance department to assure that the equipment is maintained properly and that the quality of the equipment is not to be compromised.

To manage the same, Odoo ERP Maintenance Module which can provide the various maintenance protocols like, maintenance request, storing the equipment etc.,

To begin with, maintenance teams are created for various purposes. Once this is done, the equipment that are used in the Organization can be added. If any equipment defect or any malfunctioning occurs, they can be reported immediately by creating a Maintenance Requests. The maintenance team will take action for the same and the maintenance stages can be updated simultaneously.

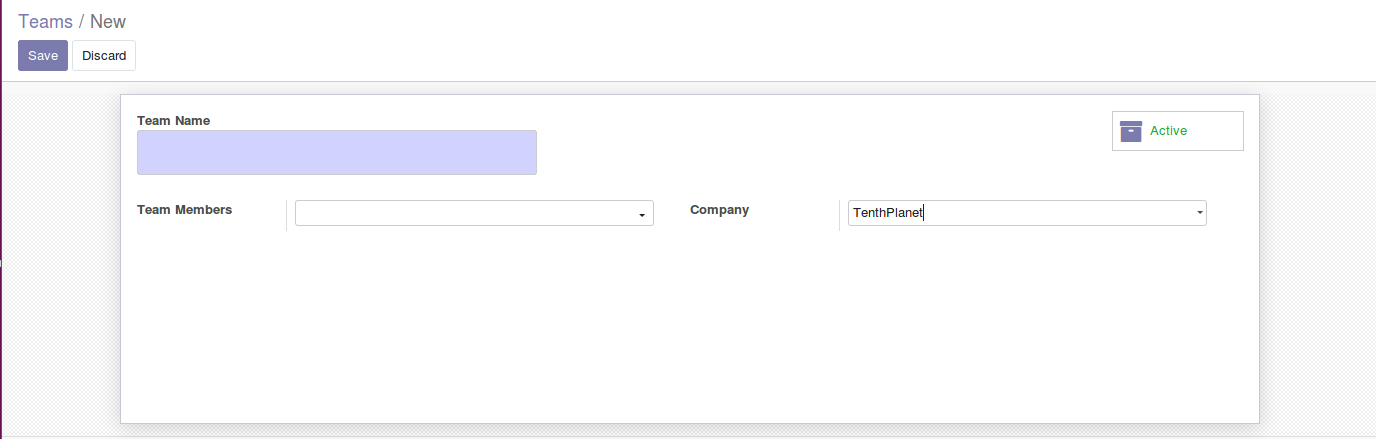

Maintenance Teams

Maintenance teams are required for a systematic approach to solve the maintenance requests that are created.

To complete the maintenance team, the following data has to be entered,

- Team name

- Team members

Equipment

Equipment can be created by entering the following fields,

- Equipment Name – name of the equipment

- Category – equipment category

- Maintenance Team-the team that is in-charge for the equipment

- Description – description of the equipment

In addition to that, product information can also be mentioned like,

- Vendor – name of the vendor

- Warranty – warranty period

- Model – the equipment model

Maintenance information like,

Preventive maintenance Frequency: This is set by entering the number of days.

Next Preventive maintenance: This field will be updated automatically based on the Preventive Maintenance Frequency field. If the Preventive Maintenance Frequency is set as 30 days, Next Preventive Maintenance will be updated accordingly based on the current date.

Maintenance duration: Hours for maintenance.

Once the equipment is created, the maintenance requests that are pending will show in the top right corner of the equipment page. By this, the maintenance team can scan or check equipment wise also.

Maintenance Requests

Maintenance requests are created when there is any defect in the equipment that is being used by the Employees.

While creating a maintenance request, the main highlight is that, the request can be differentiated if it is a Preventive or a Corrective request.

Preventive maintenance is done before the equipment meets a failure, like, servicing the equipment on regular intervals.

Corrective maintenance is the support done on equipment upon its failure.

To create a Maintenance request, update the following data,

- Team – select a respective maintenance team

- Scheduled date – date in which maintenance has to be completed

- Priority – priority of the request

- Internal note – additional information

The stages of the request can be updated by the maintenance team,which are,

- New Request

- In Progress

- Repaired

- Scrap

These stages can be maintained in a pipeline view.

Here, the Closed date field will be automatically updated when the request reaches the ‘Repaired ‘stage.

Maintenance Calendar

The requests that are created by the Employees,can be viewed in a calendar format. Also,maintenance requests can be added from the calendar view as well.

By this, the maintenance teams can schedule themselves and set a target for the a or a week and complete the created requests.

Maintenance Reports

The maintenance requests that are created can be viewed in the form of reports.

Graph view : shows the tickets completed by every team member.

Pivot view : displays the data according to various categories like,equipment category,department,employee.

Kanban view : the requests are placed in a pipelined format according to the stages.

With the help of this,manual reports need not be generated with respect to the maintenance requests.