How to have an Always-On Inventory using OPC and SPC

Introduction

Inventory management is a good practice for any company. If you are not keeping a watchful eye on your inventory or counting stock regularly, you are setting yourself up for potential inventory errors and challenges.

Proper inventory management really can make or break your business! This is where our Optimal Product Catalog and Sales Process Control Methodology comes into the picture with sole purpose of creating an Always-On Inventory with product which your customers actually need and are purchasing.

Some of the benefits of using an Inventory Management Methodology are;

- Satisfied Customer’s.

- Organized Warehouse.

- Improve Cash Flow.

- Customer focused Warehouse.

Approach

Data is collected from various sources and loaded to data warehouse using Pentaho+ Data Integration. The Pentaho+ Data Integration Tool performs the cleansing, transformation, applying rules and stores in data warehouse.

This data is further used for the exploratory data analysis, creating data pipeline and building model. The outcome of this is visualized in Pentaho+ dashboards build using Pentaho Plus CTools.

How OPC and SPC Combination Helps

OPC stand for Optimal Product Catalog, SPC stands for Sales Process Control. SPC focuses on Sales performance, whereas OPC uses multiple features to determine a score of the product, some of the features which are being considered are;

- Bill Count of the Product.

- Quantity Sold.

- Sales Amount.

- Profit Obtained.

Using the above mentioned features a scoring model is generated through which each of the product is scored, though scoring is usually done using top to bottom approach, that is, we begin scoring in terms of Category, Brand and Product.

In order to have an Optimal Inventory it is necessary to know and understand what different Category your customers are focused to buy, then drill to Brand level for each category and then to product, this actually helps to focus on certain Category/Brand/Products which can be stocked up as per your Customers purchase pattern.

While OPC provides you with Scoring Metric in terms of Category/Brand/Product to understand which Category/Brand/Product is performing better, the SPC provides an Decision Control Chart for each product which has a higher score outcome, this actually aids in making decisions in terms to whether to stock up a product purely based on score or check it’s overall sales performance using SPC Methodology and then make a decision of whether to hold up onto that product in inventory or drop the same.

Let’s take an example of a Retail Analytics solution which uses this OPC and SPC Methodology to have an Optimal Inventory.

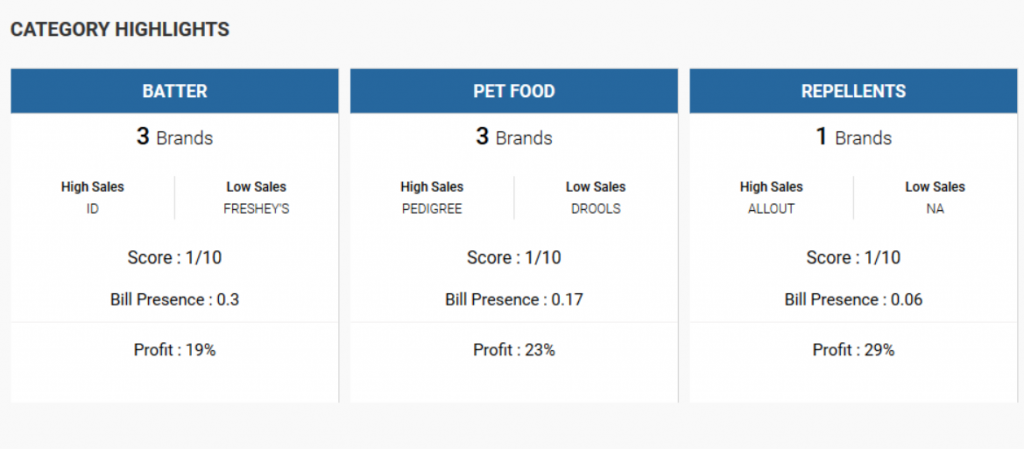

The above image is a snapshot of the dashboard, which uses OPC methodology to provide scoring metric in terms of Category, as can be noted in the image above, the Category – Batter, has a total of three brands in it, and overall score while compared to other categories present in the said store, this category has a bill presence of approximately 30%.

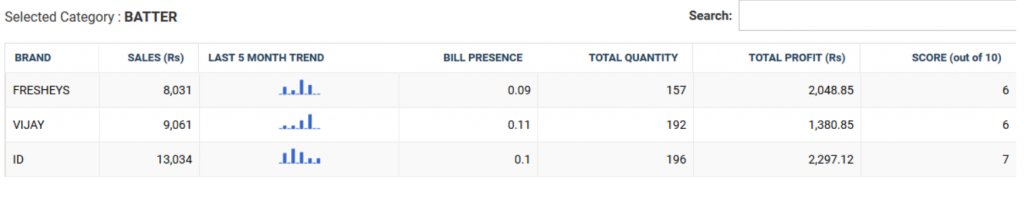

On further drill-down, we obtain a Brand specific scoring outcome, the image represented above determines how each brand has been scored and its subsequent information such as Sales Amount, Bill Presence, Quantity Sold and Total Profit.

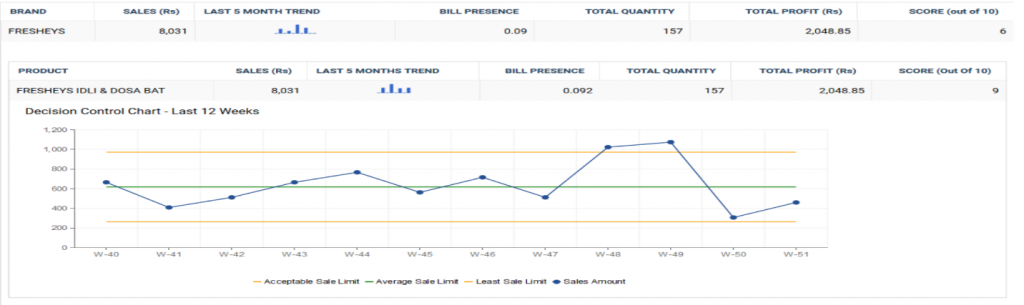

On further drill-down, we get product level details and score along with the ‘Decision Control Chart’, the chart provides last three months sales outcome and how the product is performing. Based on the product level outcome and the chart observations, one can make a decision of retaining the said product and storing adequate levels of the items in their inventory.

Conclusion

Inventory is the bloodline of your business, managing it efficiently is the only way to streamline your costs, improve revenue and obtain an enhanced customer experience. Both OPC and SPC strives to provide an optimal inventory management experience for your businesses.